Welcome to PhiDrillSim

Optimize drilling operations with real-time data

Experience seamless drilling operations with real-time data from our advanced well-planning tools.

Effectively manage stuck pipe scenarios and prevent drilling interruptions with precision solutions.

Optimize torque and drag control for improved drilling performance and operational efficiency.

Prevent well collisions and ensure safety with our cutting-edge anti-collision management system.

Control vibrations in drilling operations and enhance overall stability for a smoother workflow.

-

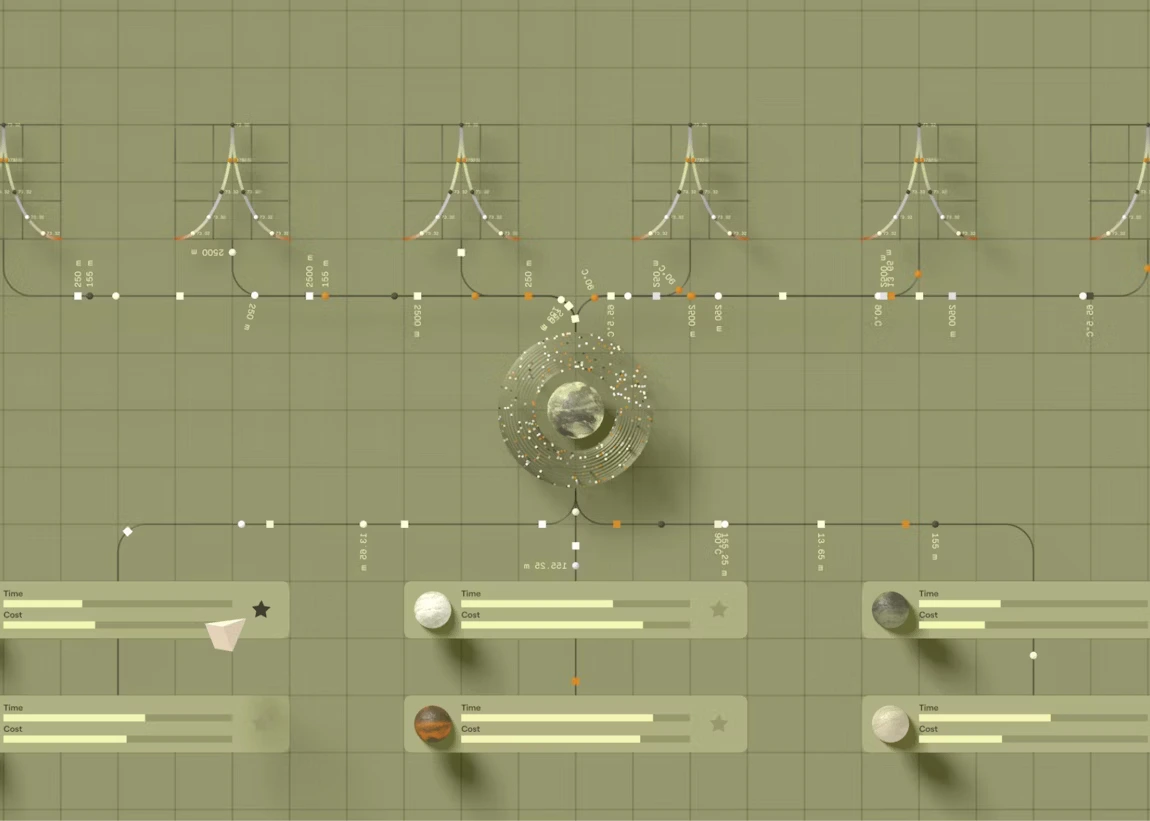

Well Planner

Plan well drilling operations -

Well Control

Manage well control operations -

Torque and Drag

Analyze torque and drag loads in drilling strings -

Vibration Management

Manage drilling vibrations -

Anti-collision

Prevent well collisions -

Stuck Pipe

Manage stuck pipe scenarios

Join the PhiDrillSim Community

Become part of the PhiDrillSim community for cutting-edge drilling technology solutions, real-time well control, and enhanced operational efficiency. Join us on our platform here.5000+

Sim Well Drilled500000+

Sim Bits Runs10000+

Sim Meters Drilled5 Key Solutions for Your Drilling Needs

Discover tailored drilling solutions designed to enhance operational efficiency and safety.Well Control Solutions

Anti-collision Systems

Torque and Drag Control

Stuck Pipe Management

Vibration Management

Our Supporters

Don't worry, we got you. Our support do kinikan sha.

It's a Match

News from our team

We can't explain ourselves like our customers and their numbers can. Listen us from them.

testmonials

Hear What Others Say

Discover what our valued clients and partners have to say about their experiences working with us.

CETAC

CETAC